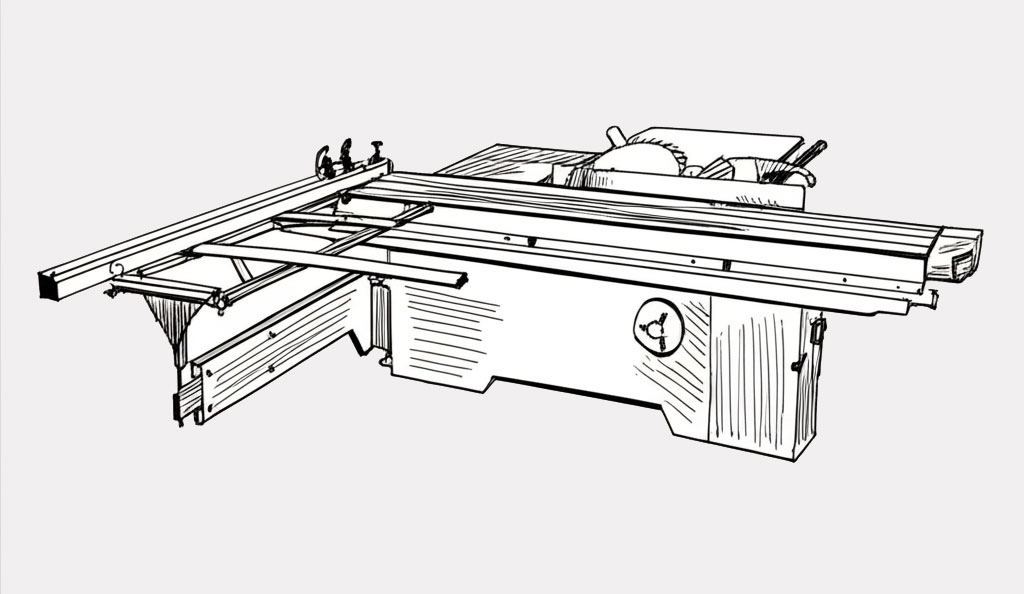

The invention of the sliding panel saw was seen as a major advancement in woodworking because it transformed efficiency, safety, and accuracy in handling large sheet materials and precision assemblies:

- Increased accuracy: The sliding table allows the workpiece to move smoothly and precisely past the blade while remaining fully supported, reducing human error and ensuring consistently straight, clean cuts—especially important for cabinetry and furniture making.

- Safer operation: With the material firmly on the sliding table, the operator can keep hands farther away from the spinning blade. This design also eliminates much of the awkward lifting and repositioning required by older saws, significantly reducing the risk of accidents.

- Time and labor savings: The sliding mechanism enables one person to cut even large or heavy panels easily, speeding up workflow and reducing the manpower needed for big jobs. This efficiency was a huge benefit compared to handling cumbersome sheets on older static table saws.

- Versatility: Sliding saws can perform complex cuts—rip, crosscut, bevel, and mitre cuts—with greater ease. The sliding feature also allows for cutting larger panels, enabling the woodworking industry to utilize modern sheet materials (like plywood, MDF, melamine) more effectively.

- Foundation for automation: The sliding mechanism set the stage for later integration with digital controls and computer automation, further enhancing productivity, precision, and repeatability in industrial settings.

Overall, the sliding panel saw’s combination of safety, speed, accuracy, and the ability to handle large panels fundamentally modernized woodworking, supporting both small custom shops and large-scale furniture manufacturing.